The Chuck Cleaning Wafer (CCW) product was developed to trap and remove loose debris from the wafer chucks and handling hardware.

The CCW is built using a highly cross-linked, sticky polymer mounted on wafers that are then cycled through the process tool.

This unique cleaning material does not out-gas (ASTM E595) nor is it observed to transfer any metallic or organic material (ICP-MS and XPS). The CCW product has an upper working limit of 300C.

Low Cost of Ownership: The CCW product can be used up to 20 times before becoming saturated with particles.

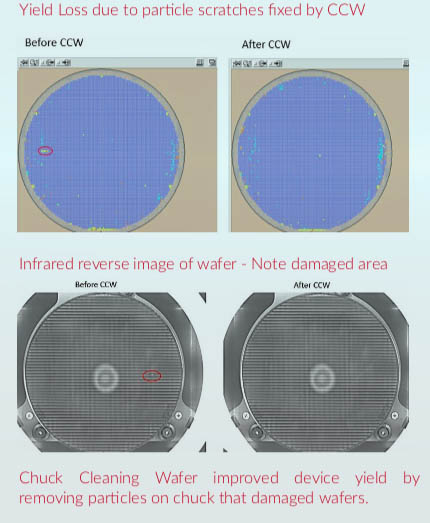

During the wafer test, particles on the prober chuck can cause device damage, yield loss, or thin wafer breakage. Manual cleaning requires long downtimes, particularly for high or low-temperature prober chuck conditions.

Products

Etch Clean® – Method to Eliminate ESC flow faults without opening the chamber

Stage Clean® – Method to Eliminate Lithography Hot Spots with No Downtime

PVD CCWTM – Eliminate PVD backside pressure faults without opening the chamber