We are experienced in supporting Fabs of all sizes and applications to monitor and manage yield-affecting contaminations. Our fast response, localized on-site services, and unlimited support compliments the products we offer into a comprehensive solution to meet your requirements.

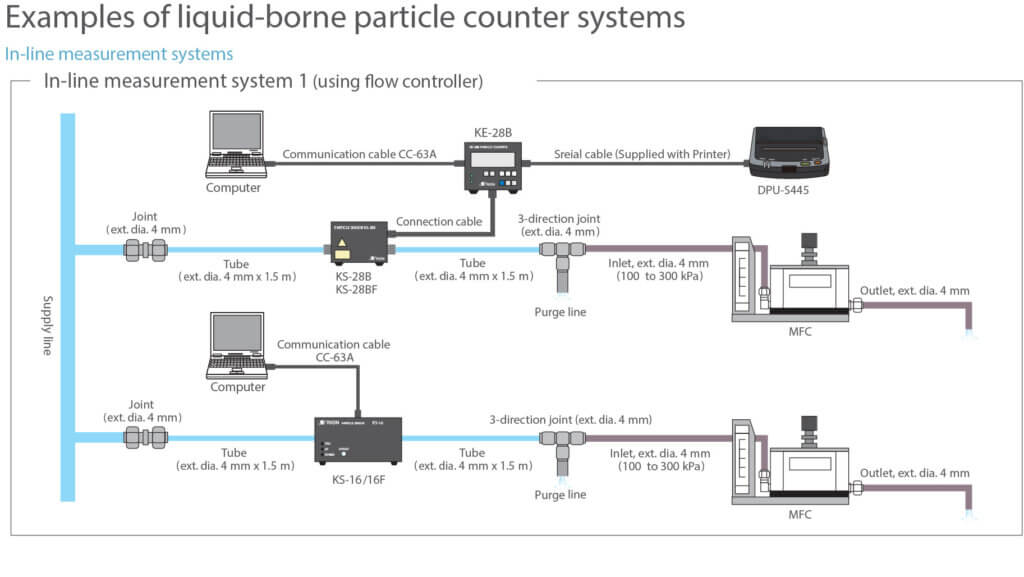

Liquid Particle Counting

- Batch Applications : gate and measure quality of chemical deliveries to protect bulk chemical tanks, reduce filtration burden, prevent excursions

- Inline Applications : filtration and final polishing monitoring, Particle Defense Line, bulk chemical delivery monitoring, new filter flushing checks, and UPW monitoring

- Chemical Compatibility : PFA and glass/sapphire wetted parts ensures resistance and compatibility with UPW, aqueous, solvents, blends, acids, HF, bases, and corrosives.

- Cost Effectiveness : able to measure a wider range of refractive indexes and chemicals than competitor units, modular design enables each switch between batch and inline

- RION’s superior counting efficiency measures more of the liquid passing through the sensor to allow detection of small fluctuations and more stable data trends

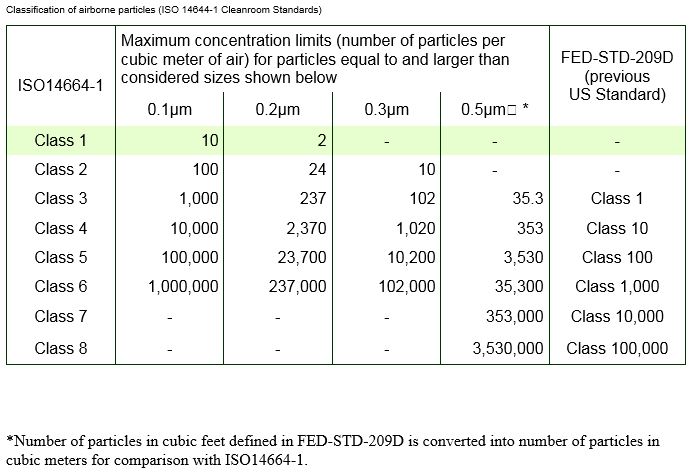

Air Particle Counting

- Handheld / Portable : particle source detection, clean-room qualifications, spot checks, move and measure

- Multi-point / Manifold : continuous monitoring of production / filling area cleanliness, 0.08um and 0.10um capable, sampling tubes enables connection to tools and enclosed spaces

- Capabilities: 0.08um and 0.10um capable

- ISO 21502 (JIS B 9921): high flow-rate and high counting efficiency

Ultrasonic Concentration Meters

- Applications : feed chemical monitoring, chemical blending, quality control

- Fast : real-time measurement, no more waiting for lengthy titration

- Accurate : superior to conductivity meters, temperature compensating

- Flexibility : flow-cell type, flanged type, and explosion proof models

- Easy to Maintain : no consumables, self calibration / verification

Portable Cleanzone System

- ISO Class 1 capable : less than 10 particles/m3 at 0.1um

- Fast : establishes a clean-zone in less than 3 minutes (Turn off when not in use)

- Portable : plug-n-play, standard electric outlet

- Cost Effective : lower initial cost AND operating cost than standard traditional clean-room

- Applications : Ultra-clean protection of sensitive test samples, critical processes, and instruments. Localized filtration of particle generating spots

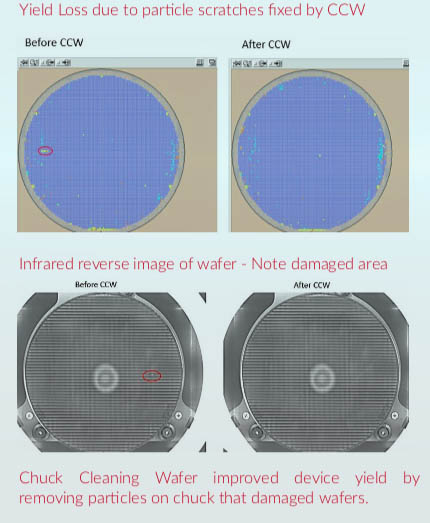

Litho, Etch, PVD Tool Cleaning – CCW

- Chuck Cleaning Wafers enable online cleaning to eliminate lengthy tool downtime and associated costs

- Eliminate ESC flow faults without opening the chamber

- Eliminate Lithography Hot Spots with No Downtime

- Eliminate PVD backside pressure faults without opening the chamber

- See how it works