SWE Series – SWE Series is designed to remove debris and maintain shape of cantilever, vertical, round, crown-shaped probe tips. The unique structure combines an adhesive layer with a wavy cushion layer that has abrasive coated directly on top. Abrasive sizes available are 4K(3um), 6K(2um), 8K(1um) and 10K(0.5um). SWE provides excellent cleaning performance at a very low cost.

LC4K, LC6K, LC8K, LC10K – Same structure and performance as MIPOX SWE products, but with new low chlorine formulation and process. The presence of chlorine ions and chloride contamination on a bond pad surface can act as a catalyst for the copper (Cu) corrosion process and dramatically weaken the copper-aluminum (Cu-Al) intermetallic compounds (IMC). Reduced bond integrity can create long-term reliability issues for packaged devices.

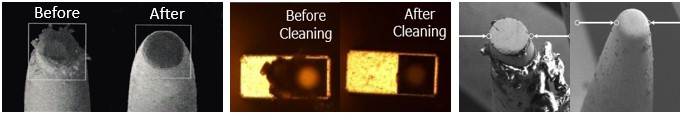

Probe Polish®(PP70, PP99, PP150) – Probe Polish® is designed to remove embedded and bonded debris from probe tips and collect any loose debris that was generated during probing. The abrasive material in the polymer will remove the accumulation of embedded or bonded debris but is not so aggressive that it will alter the probe material or probe contact area.

Probe Lap® – Probe Lap® built using aluminum-oxide (PL-xxAH) or silicon-carbide (PL-xxSH) abrasive grit can be mounted on various substrates and abrasion plates used for on-line and off-line probe cleaning.

Probe Form® – Probe Form® was developed for cantilevered probe technologies to provide a cost-effective method of uniformly “reforming” a flat probe tip into a radius shape with a smooth contact surface. Probe Form® uses a highly crosslinked, non-corrosive polymer that was designed aggressive enough to remove probe material.

Probe VerticalTM – Probe VerticalTM is designed to remove embedded and bonded debris from vertical probe tips and collect any loose debris generated during probing. The abrasive material in the polymer will remove the accumulation of embedded or bonded debris. Probe VerticalTM (ADOE) is designed to maintain the pointed or cone shape of vertical probe needles during the cleaning process.

Specialty Cleaning Materials

Probe Clean® – Probe Clean® is designed to remove loose debris, which is generated during probing. It is not designed to remove embedded or bonded debris. The removal of embedded or bonded debris requires products such as Probe Scrub® or Probe Polish®.

Probe Scrub® – Probe Scrub® is designed to remove embedded and bonded debris from probe tips, collect any loose debris, and lightly polish the flat tip probes during probing. The material provides excellent results during room temperature probing operations and at elevated temperature conditions (‘hot chuck”) up to 125°C.

Probe RefreshTM – Probe RefreshTM can be mounted on various substrates and abrasion plates used for on-line and off-line probe cleaning. In all instances, Probe RefreshTM is a more effective replacement for similar on-line lapping film applications.

Assembly Clean® – Assembly Clean® is designed to remove loose debris, which is generated during the assembly process and stuck to the pick and place hardware. It is not designed to remove embedded or bonded debris. The removal of embedded or bonded debris requires abrasive products such as Probe Polish®.

AO3K, AO8K Fiber Film – Fiber Film sheets are typically used for a chemical mechanical polish (CMP) and optical connector polishing at ambient temperatures. These sheets are an abrasive pad constructed with 3mm to 5mm long fibers that have been embedded into a poromeric foam layer. The tiny fibers are coated with aluminum oxide abrasive particles and a resin binder.