Contamination monitoring and control is still important at the back-end of the semiconductor manufacturing. Prevention and removal of contaminants from the process and testing tools are critical to improve yield and maintain high quality and profitability.

Probe Card Clean

- Improve yield

- Easier and less downtime than manual cleaning

- We offer both Mipox and ITS brand products with a wide variety of structures, shapes, sizes, loading, abrasive size, and aggressiveness.

- Cleaning wafers, chucks, self-application sheets for both online and offline needs

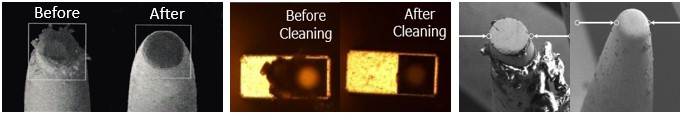

Probe Card Conditioning

- Clean and reconditions probe tips to extend functional life

- Maintain tip shape for proper contact and oxide penetration

- Products include Probe Form, Probe Refresh, SWE, LCxK

- Customized solutions available

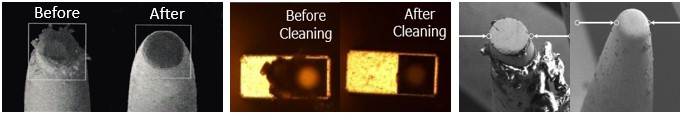

Test Contactor Cleaning

- Improve yield

- Easier and less downtime than manual cleaning

- ITS surrogate chips offer fast and automated online cleaning process

- Mipox low cost solutions for offline cleaning

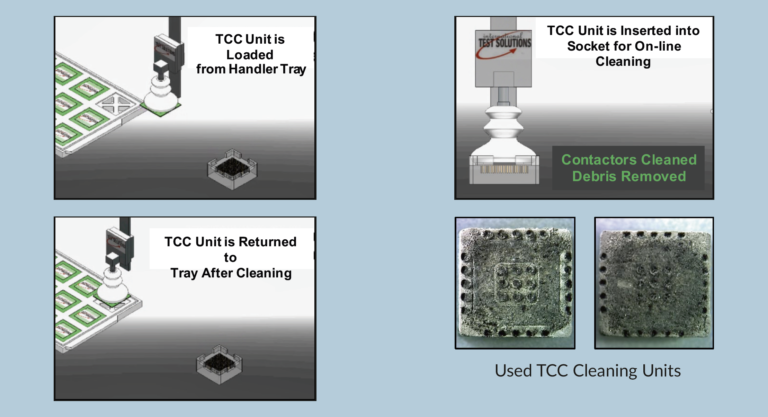

Portable Cleanzone System

- ISO Class 1 capable: less than 10 particles/m3 at 0.1um

- Fast: establishes a clean-zone in less than 3 minutes (Turn off when not in use)

- Portable: plug-n-play, standard electric outlet

- Cost Effective: lower initial cost AND operating cost than standard traditional clean-room

- Applications: Ultra-clean protection of sensitive test samples, critical processes, and instruments. Localized filtration of particle generating spots

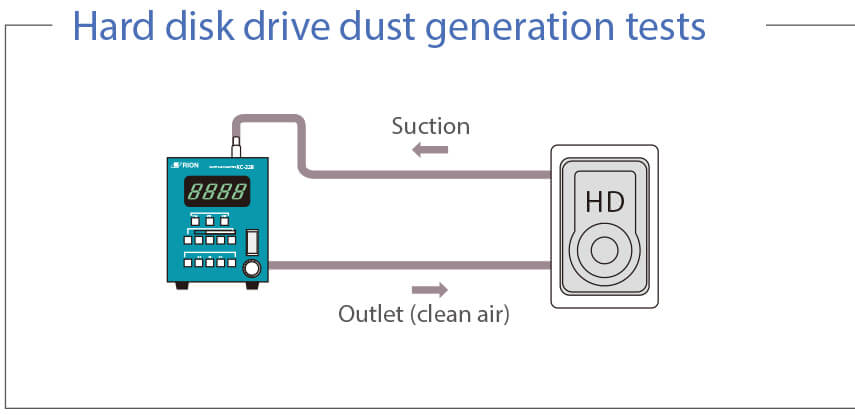

Air Particle Counting

- Handheld / Portable : HDD particle generation test, particle source detection, clean-room qualifications, spot checks, move and measure

- Multipoint / Manifold : continuous monitoring of production / filling area cleanliness, capable down to ≥0.08um and up to ≥100.0um, sampling tubes enables connection to tools and enclosed spaces

- Various flow-rates available to meet application requirements